Controversy about Refrigerant Charge

“So why does my contractor keep ‘topping off’’ the Freon® in my system?"

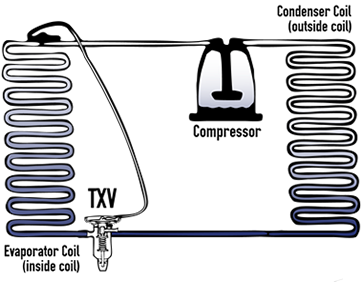

If he has not told you why, then he is ripping you off. As shown in this figure, an air conditioner is a closed system. Refrigerant isn’t USED UP in a system. Unless there is a leak, the refrigerant is there for as long as the system is in place.

It is unfortunately quite common for technicians to add and remove refrigerant without proper diagnosis.

In 1989, based on work by Leon Neal, NIST and the AC manufacturers, Proctor Engineering began enforcing the manufacturers’ near universal specification for testing and adjusting the amount of refrigerant in air conditioners.

Freon, Efficiency, and Energy Codes

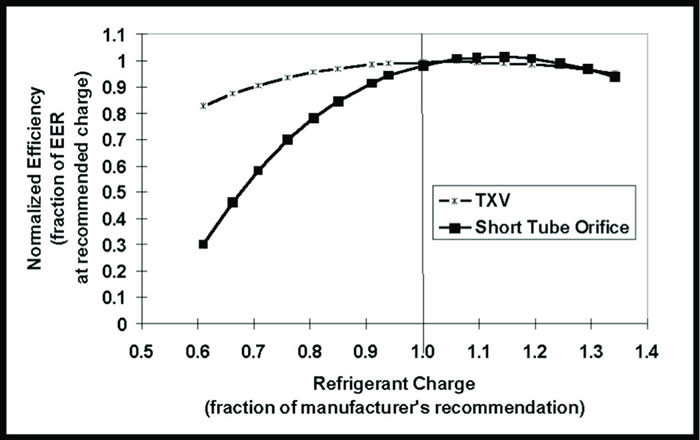

Air conditioners efficiency changes depending on the amount of refrigerant often referred to as Freon® -- a DuPont brand name for chlorofluorocarbon refrigerants. The graph below was produced by Proctor Engineering in cooperation with Pacific Gas and Electric Company and the California Energy Commission (CEC).

Proctor Engineering Group’s work with the CEC led to changes in the Title 24 Building Energy Efficiency Standard: first incorporating the option of a TXV or refrigerant charge testing and later specifying refrigerant charge testing for all new and replacement installations of air conditioners and heat pumps. Simultaneously, Proctor Engineering Group delivers CheckMe! Quality Assurance Programs for AC efficiency improvements to a variety of utilities and state entities. Working directly with the technicians and analyzing the results of these programs as they progress, PEG has found areas for improvement. These areas include:

Analog refrigerant gaugeS are out of calibration more than half the time. Digital refrigerant gauges are now specified in all Proctor Engineering Group programs.

Analog refrigerant gaugeS are out of calibration more than half the time. Digital refrigerant gauges are now specified in all Proctor Engineering Group programs.

- Line temperature measurements used in calculating superheat and subcooling are subject to large errors when the temperature is measured with clamp on sensors that are insufficiently insulated from ambient air and when they are subject to air currents at a temperature different from the line temperature. The best current solution is taping a thermocouple directly to the line, fully insulating it, and protecting it from any air movement.

- Suction line temperature measurements are subject to large errors unless the sensor is placed on the upper quadrant of the suction line.

- The manufacturers’ specifications for superheat and subcooling are appropriate for new installations only. Using those specifications for post installation checks and tuneups ignores the normal variations that occur under different ambient conditions and inevitable variations even in calibrated test equipment. Using the manufacturers’ specifications also produces a large number of very small refrigerant adjustments that do not achieve any significant savings. Proctor Engineering Group’s program designs are now targeted to produce adjustments that provide at least a 5% improvement in efficiency.

Energy-Saving Solutions

- My utility bills are too high!

- Could my asthma be related?

- How do I know my AC is working efficiently?

- Does it really make any difference?

|

Morbi turpis augue, varius in vehicula vitae. Murus onare. Suspendisse potenti. Aliquam vel mi purus. Pacific Gas & Electric |